Impact

By Julia Scott

We may not think of indoor light as a sustainable source of power, but it is. Indoor light can be harnessed to power numerous home devices that surround you already: think of electronics that use sensors, such as thermostats, light and motion sensors and smoke detectors, to name a few.

This sounds like a magic trick, but it is the result of a solar cell printing process by Epishine, a Sweden-based company that is on a major growth trajectory. Epishine’s products are already in the marketplace, invisibly powering devices embedded inside consumer electronics, in building automation technology and along global supply chains.

Now the company is moving forward in its mission not just to obtain commercial success, but to keep disposable batteries out of landfills and fight climate change by saving on electricity.

“If we’re going to make a big difference in combatting climate change, we need something you can roll out fast. There are very few technologies where you can achieve this,” says Anders Elfwing, co-founder and Passion Manager at Epishine.

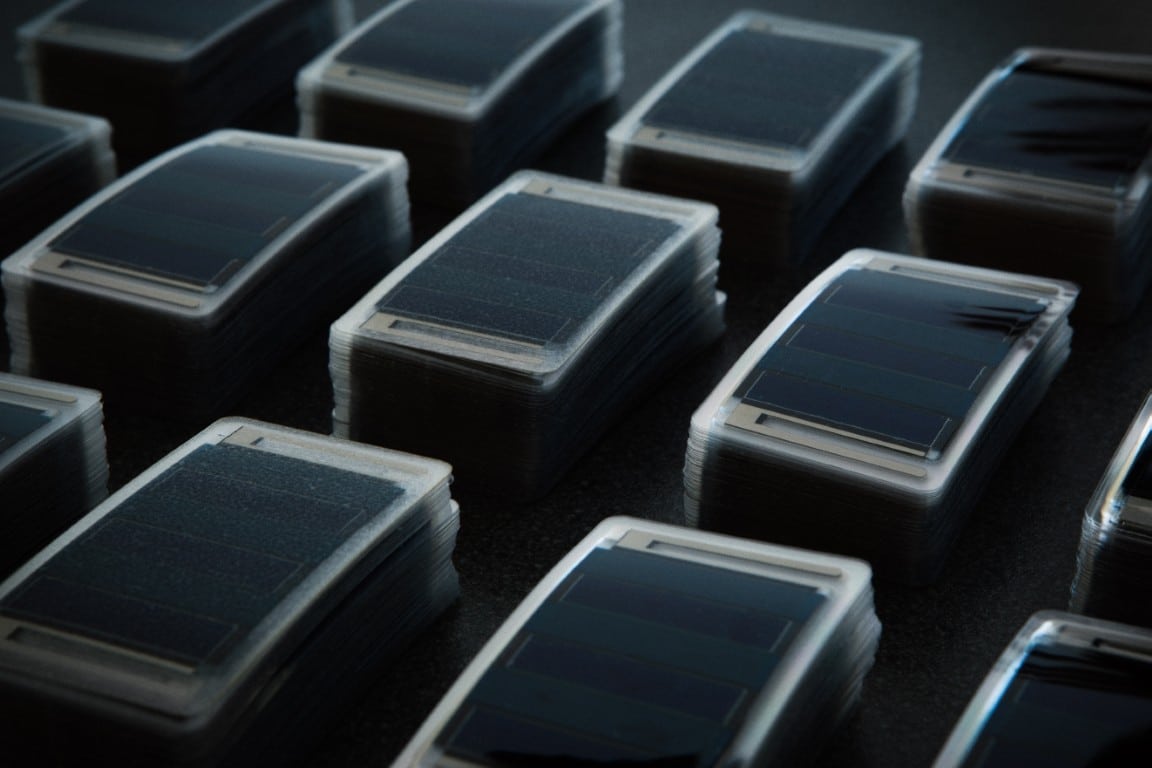

In Epishine’s process, solar cells are encapsulated inside flexible PET plastics that measure no more than 0.2 millimetres in thickness. This type of solar cell is much more compact than what typically powers outdoor photovoltaic panels, allowing for inclusion in small devices. Epishine uses polymers instead of silicon, which is the semiconductor material traditionally used in most photovoltaic panels.

With a background in biomolecular and organic electronics, Elfwing was part of a team at Linköping University that iterated multiple prototypes for Epishine’s signature organic photovoltaic polymer printing process. In 2016, he and other scientist colleagues co-founded Epishine with Mattias Josephson, who is also the company’s Chief Strategy Officer. After years of research, the team was confident the moment was ripe for their technology.

“This is the first real breakthrough product based on these kinds of electronics,” says Josephson, an entrepreneur who had sold his previous company to Motorola.

The multifaceted uses for indoor solar cells stretch far beyond consumer and home electronics to commercial buildings, grocery stores and warehouses. And that is where Epishine has seen major adoption of indoor light harvesting devices.

More and more of our world’s processes are becoming digitised, from electronic asset trackers that replace barcodes on boxes to electronic price tags in grocery stores. “It could take 40,000 batteries to replace those price tags in a single store,” says Josephson. “In shipping, you want to follow every package sent around the world. There are billions of small, connected things that need to be self-sufficient to really be maintainable.”

Today, Epishine manufactures and designs components for products deployed across Europe, North America and Asia, generating 1.1 million euro in revenue. The company has raised 25 million euro in private investments from family offices in Sweden with 40 employees. It also received early-stage funding from the Swedish Energy Agency, Horizon Europe and Eurostars.

In 2022-2023, a Eurostars project facilitated a key partnership with Brilliant Matters, a Canadian company that makes specialised printing inks for solar cells like Epishine’s.“Brilliant Matters will be able to put more of its product on the market, and we will be one of the purchasers of that material,” says Elfwing.

As the internet of things expands, so too does the scope of possible uses for Epishine’s solar cells. And although the concept of utilising indoor light is not new (some may remember the solar-powered calculators many of us used to do schoolwork from as early as the 1970s).

Epishine’s technology differs in materials and construction from previous solar cell models. It has increased their performance in low light and made electronic devices much more reliable. There is no limit to how many the company can print, and capital expenditures are low.

“We have achieved something that people have been trying to do in different industries for a quite long time. And the feedback we have received several times is, ‘This is fantastic. Now it finally works,’” says Josephson, who points out that their process uses a hundredth of the electricity needed to manufacture silicon-based solar cells, and a hundredth of the materials too.

But it is not about competing with silicon. Josephson sees Epishine’s mission as making the business case for an emerging energy source that will complement other existing technologies, which, taken together, have a positive environmental impact.

“Based on our calculations, by 2028, there will be about six billion devices sold globally that could be powered by indoor light,” he says. By harnessing indoor light, the technology’s potential for sustainable change is unlimited.

Through our funding programmes, national/regional funding bodies support SMEs, large companies, universities and research organisations conducting R&D and innovation projects together beyond borders to achieve great results. Learn more about our programmes and discover whether we have a funding opportunity for your organisation.

Eureka programme and project name: Eurostars-3 IMPACT

Countries involved: Sweden and Canada

Project duration: 2022-2023

Eureka programme and project name: Eurostars-3 SELECT

Countries involved: Sweden, France, Norway and United Kingdom

Project duration: 2024-2026

Eurostars is part of the European Partnership on Innovative SMEs. The partnership is co-funded by the European Union through Horizon Europe.

Got an innovative idea? Explore our funding opportunities designed to support groundbreaking projects and help turn your vision into reality.

Secure the resources you need to bring your ideas to life.

See all open calls